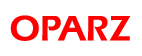

Differencial pressure characteristics depending on the combination of Palblat (normal temperature setting)

There are three types of Palblat as a material for the heater and the trap - 04 (Fine), 12 (Medium), 25 (Coarse). Various combinations are available to meet the purpose of application.

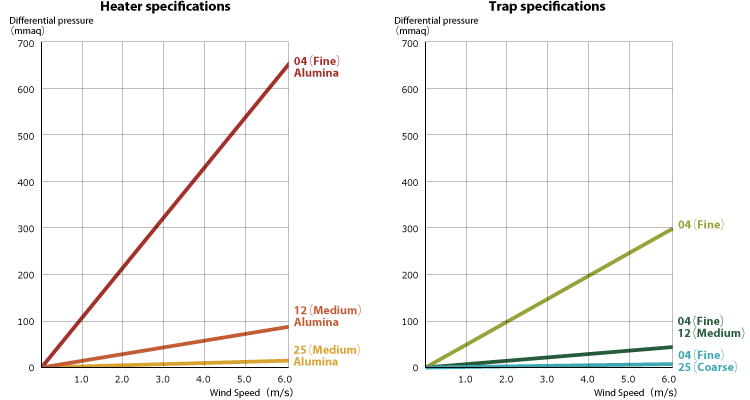

Heating property characteristics by Palblat type (at a constant flow rate)

Specification

Since we will design the heater by ventilation conditions, please contact us.

| Heater specifications example | Φ50 | Φ100 | Φ150 | Φ200 | |||||

|---|---|---|---|---|---|---|---|---|---|

| Use Palblat: S04-30 (30µx30mm) * Mesurement condition:Calm environment |

100V | 200V | 100V | 200V | 100V | 200V | 100V | 200V | |

| Maximum surface temperture | 1000°C | ||||||||

Specification 1  |

Total resistance (Ω) | 4.09 | 16.38 | 36.85 | 65.5 | ||||

| Heating-up time (S) | 2.4 | - | 38 | 9.6 | 193 | 48 | 612 | 153 | |

| Power range (W) | ~2400 | - | ~600 | ~2400 | ~270 | ~1000 | ~153 | ~600 | |

| Power density (W/cm³) | ~41.49 | - | ~2.59 | ~10.37 | ~0.51 | ~2.05 | ~0.16 | ~0.65 | |

Specification 2  |

Total resistance (Ω) | 1.02 | - | 4.09 | 9.21 | 16.38 | |||

| Heating-up time (S) | 0.6 | - | 9.5 | 2.4 | 48 | 12 | 153 | 38 | |

| Power range (W) | ~9700 | - | ~2400 | ~9700 | ~1000 | ~4300 | ~600 | ~2400 | |

| Power density (W/cm³) | 165 | - | 10.37 | 41.49 | ~2.05 | ~8.20 | ~0.65 | ~2.59 | |

Specification 3  |

Total resistance (Ω) | - | - | 1.82 | - | 4.09 | 7.28 | ||

| Heating-up time (S) | - | - | 4 | - | 21 | 5 | 68 | 17 | |

| Power range (W) | - | - | ~5400 | - | ~2400 | ~9700 | ~1300 | ~5500 | |

| Power density (W/cm³) | - | - | 23.34 | - | 4.01 | 18.44 | 1.46 | 5.83 | |

- * The heating temperature is measured within the range 25°C ~ 325°C in the still air.

- * For a heater protection, the relay should be used with a contact capacity of more than twice the normal heater capacity.

Note for operation:

The heater control and the melting prevention

- The melting point of the heater material = Palblat is 1360°C.

The upper limit in continuous operation is considered to be 1000°C. - Regarding the temperature control of the heater during operation, please place the temperature sensor so that it is located about 1/2 of the heater radius and of about 1/2 of the thickness. And please do ensure the isolation of temperature sensor between the compression fittings.

Heater surface temperature in this case is the upper limit 900°C considering the overshoot. (C · F, Temperature sensor with insulation sleeve is optional to purchase) - Please use the heater in the state that does not cause condensation in order to prevent leakage.

If it is necessary to be used in high humidity, please keep the heater in dry condition with 80°C or higher while not in operation.

The same is true when recovering from a power failure.

Other note, etc.

- Regarding the quality of bolts and the embedded tube for the heater, please use the parts such as SUS304 corresponding to the gas components and the operating temperature.

- The inorganic metal dust in the target gas should be removed by the pre-treatment stage.

- For explosion-proof, please pre-process the flammable gas by diluting (concentration adjustment by water vapor or oxygen) and keep it within explosive (= flammable) limit.

Also please prevent a flash fire by applying a trap to the position more than 30mm over the upstream side of the heater.